Drawer Slides Defined

The term “drawer slide” is a term used to describe a mechanism that mounts to the side of the drawer and to the side of the cabinet or the cabinet frame. “Slide” is the blanket term used in the industry for all ball bearing slides, telescopic slides, glides, drawer runners, linear slides, rails, linear motion tracks and various other guides or linear motion technology. For most, drawer slides are what we typically use to allow a drawer or tray to slide in or out of a cabinet or enclosure.

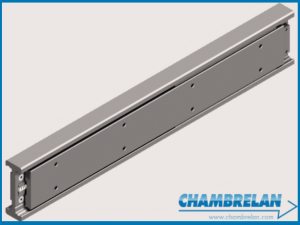

We’re proud to represent not one, but THREE of the world’s leading manufacturers of drawer slide motion technology: Accuride International, Chambrelan, and Sugatsune Canada!

What are the types/categories of slides?

There are three basic categories for drawer slides, by weight rating:

- Light Duty (capacity up to 139 lbs/63 kg per pair). These are typically used in desks, kitchens, or displays where the trays/drawers don’t hold a lot of weight. Sugatsune’s slides like the AR3-100 are an example of a light-duty slide.

- Medium Duty (capacity of 140-169 lbs/64-76kg per pair). You’d see these in some power generators (for the battery tray), in transit/highway buses (in the computer enclosures), and in medical carts.

- Heavy Duty (capacity of 170-1,323+ lbs/77-600+kg per pair). Heavy duty slides are used in the battery tray of some buses and truck bodies, toolboxes, industrial machines with slide-out components, and emergency vehicle compartments. Chambrelan has a range of slides that can achieve load ratings of up to 2,600 lbs per pair on a 70” full extension slide! The E1020 Series slide really is the definition of “heavy duty”.

There are also subdivisions based on the markets where certain slides are used:

- Commercial Slides are used in architectural designs like houses, office buildings, institutional builds, etc.. They are the kinds of slides you see most often in day-to-day life: kitchen drawers, office desks, fridges and ovens, and also filing cabinets.

- Industrial and Electronic slides are the ones that we work with most often. You’ll see these slides in trucks, buses, RV’s, medical carts, generators, and server racks, too.

- Specialty/Architectural slides, like many of the products offered by Sugatsune, are made for use in custom designed buildings, offices, and high-end enclosures or cabinets. These are typically not used in large quantities, and are for those end users that are less concerned with budget than finding the perfect part for the project.

There are a few different types of drawer slides, including ball bearing slides, friction slides (which don’t use any kind of bearing or rollers at all) and “roller runner” slides, which are slides with a single roller on the drawer and frame mount. We’re focusing mostly on the ball-bearing type of slides in this article.

How do slides work?

Drawer slides consist of several components: The “members” (the steel, stainless or aluminum frame pieces that attach to the drawer or the frame), the ball bearings, and a ball cage (or carrier). The ball bearings allow the members to roll back and forth smoothly, allowing a drawer to open and close. The purpose of the ball cage is to ensure the proper spacing of the ball bearings so they bear the weight of the drawer (and its contents) as evenly as possible, and so that they can travel along the slide length as a group. Not all slides have three members, some only have two (no middle member). Slides without a middle member can only extend to about 3/4 of their closed length.

The many uses of slides

The most obvious place to use slides is in drawers. You’ll see slides in dressers, cabinets, and toolboxes. But there are other uses for slide technology that goes into the basic “drawer”. For example, Accuride makes a product (the CB-LIFT)that incorporates one or two slides, but attaches to the back of a TV so it can be concealed in a cabinet, and raised into place with a spring (or an electric lift motor) for watching your favorite playoff game! Slide technology can also be used for things like sliding doors or pass-through windows in hospitals or high-security areas. There are so many options!

The most obvious place to use slides is in drawers. You’ll see slides in dressers, cabinets, and toolboxes. But there are other uses for slide technology that goes into the basic “drawer”. For example, Accuride makes a product (the CB-LIFT)that incorporates one or two slides, but attaches to the back of a TV so it can be concealed in a cabinet, and raised into place with a spring (or an electric lift motor) for watching your favorite playoff game! Slide technology can also be used for things like sliding doors or pass-through windows in hospitals or high-security areas. There are so many options!

Probably the most interesting application I’ve seen is for large hydroponics drawers used in the production of cannabis! The drawers are made in banks, and are built into large steel “pods” which can be stacked inside shipping containers for easy portability and scalability. Each shipping container is a fully functioning hydroponics room!

Another fun application for heavy duty slides is in camper conversions, where a long drawer is built into the floor of the van, and can be extended out the back to create a bench, an outdoor kitchen, or a long compartment that could be used for storage.

Heavy Duty / Extreme Slides

Heavy duty slides are designed to be “heavy duty” in every way: thicker material, stronger ball bearings, ball cages that are durable but light. All this, when combined with their specialized manufacturing process, creates a drawer slide that, despite its size, can withstand enormous capacities. In the case of the Accuride 9300 series slides, the slides themselves have a profile that’s only ¾” wide by 3” tall!

The largest slide I’ve seen (in terms of capacity) is Accuride’s AL4140, which has an enormous capacity of 1,323 lbs per slide! They’re milled from solid aluminum and are made to order. There are, in fact, slides that have even higher capacity, but they’re not made from solid aluminum like these ones. On the other end of the spectrum is a slide made by Sugatsune (the AR3-100), that’s only 100mm long! It’s aluminum so it’s very light weight, and the action is incredibly smooth and quiet. I’m not even sure I could design this slide into any product that would conceal the slide- it’s too nice!

There are so many applications for heavy duty slides. Among the coolest we’ve seen are for pickup truck platforms that can slide out 6 or 8 feet making the entire load more accessible. There are campervan/RV compartments with long slides that allow easy access to the deepest compartments, too!

Finding slides for your applications

Determine the “real life” load capacity of your drawer/tray. Don’t get stuck on “load capacity” specifications, and don’t let those be your only guide for picking the right slides. For example, a drawer with slides that have a 600 lb capacity may fail sooner than expected if your customers drop a 600 lb object into the drawer on a daily basis. Similarly, a 600 lb capacity slide doesn’t really have 600 lbs of capacity when it’s installed in a vehicle like a bus or a service truck. We can help to avoid that kind of problem, and save you (and your customer) some frustration.

Another key step is to make sure that your drawer and enclosure have enough room for the slides to fit comfortably, and that they provide the appropriate extension. You can then evaluate any options that are available for those slides: lock-in or lock-out, electronic latching options, push-button handles that lock or unlock the slides, and other cool features.

Our experts are happy to look at your drawings, and have a discussion with you about what your customer needs, design considerations, and more. You can visit us online to get some information about our slides, or you can call us at 1-800-318-1119 to talk with an expert immediately.